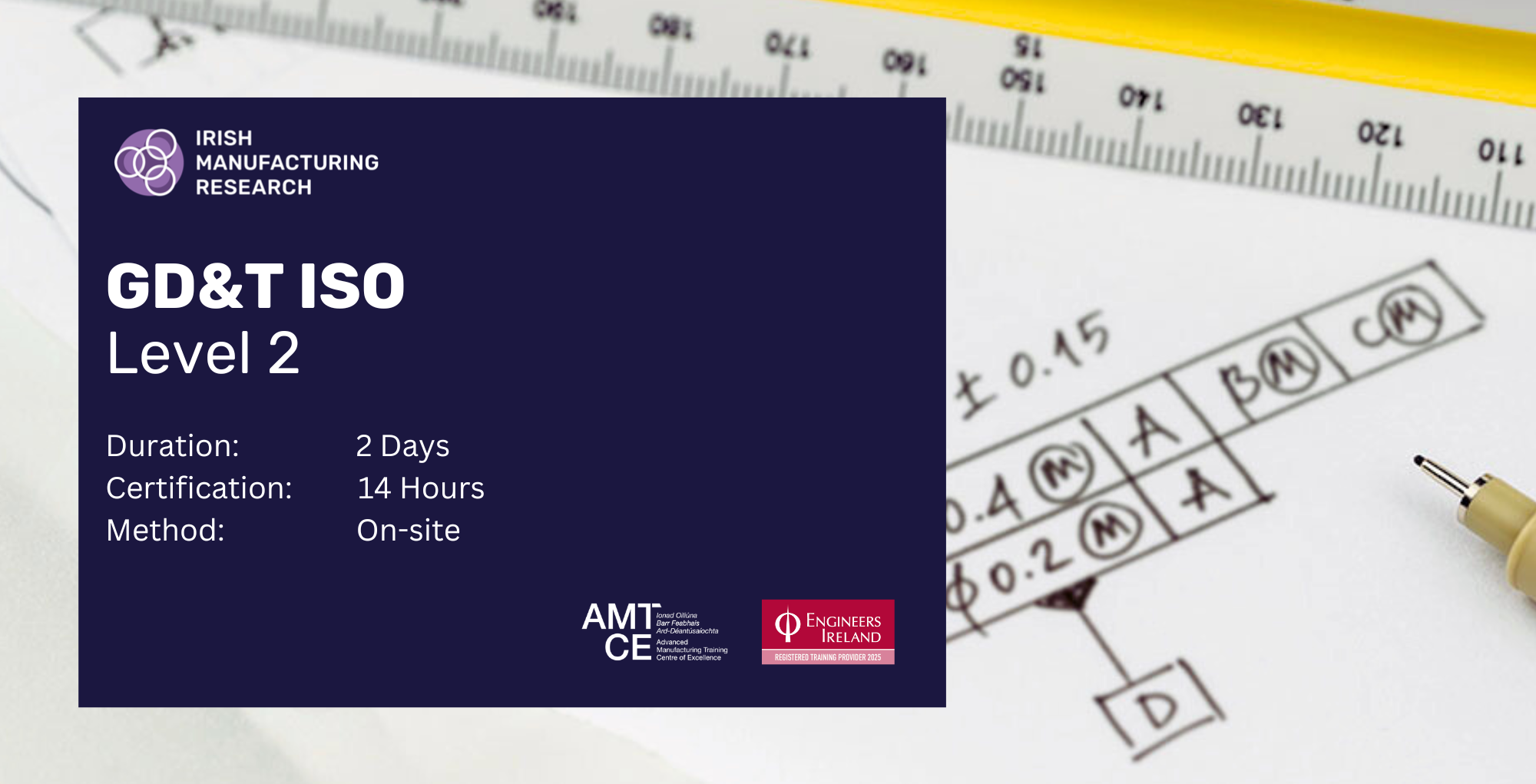

GD&T ISO Level 2

Would you have greater efficiency in product development & quality checks?

Course Aim

The course is based on BS 8888 and ISO standards (a version is also available based on the American ASME Y14.5 standard). Delegates are provided with comprehensive course notes, and a workbook with questions and exercises to accompany the training material.

Overview

The course covers more advanced aspects of geometrical tolerancing and its application and interpretation. Completion of the Level 1 course is a prerequisite for anyone wishing to attend the Level 2 course.Target Audience

The course is suitable for Designers, Engineers, Inspectors, Technicians, and Engineering Management who have completed GD&T Level 1 Course.

Course Details

- Date: Register your interest to be notified of next course date

- Duration: 2 days

- Time: 9.30 AM - 5 PM

- Method: On-site

- Location: IMR Mullingar

- Course outline: Available by request

Learning Outcomes

- Tolerance zone definitions (fixed, variable, limited, etc)

- Tolerance feature definitions (filters, associations, etc)

- Plane and feature indicators (intersection plane indicators, etc)

- Adjacent indications (UF, ‘between’, ‘all around’ etc)

- Grouping features (nX, ‘all over’, etc)

- Grouping tolerance zones (CZ, SZ, CZR, and SIM)

- Multiple tolerances applied to groups of features (e.g. hole patterns)

- Datums and ‘situation features’

- Common datums based on aligned and non-aligned features

- Datums based on groups of features

- Datums based on complex surfaces

- How location and orientation tolerances control form

- Maximum Material Requirement and Virtual Condition

- Datums based on Virtual Condition Boundaries

- Least Material Requirement

- Tolerances applied to non-rigid parts (ISO 10579 and Freestate condition)

Certification

14 hours CPD-Approved Engineers Ireland Accreditation.

Funding is available for qualifying companies. Find out if you qualify by registering your interest below.